- Excellent productivity and fuel efficiency, with more reliability reinforcement

- Optimized DEUTZ WP6G Stage II engine, high fuel efficiency from advanced design and manufacturing technology;

- Larger bucket, shorter cycle time, heavier counterweight for more payload;

- Outstanding cooling system, -20~+43 ambient temperature capability

- Optimized braking system with additional booster for reliable braking performance;

- Comfortable cabin environment, user-friendly monitor and control systems.

- Classic SEM transmission with more than 30 years’ manufacturing experience, in –house made, countershaft, power-shift design with great reliability and durability;

- SAE & DIN standard hoses and optimized routing for improved strength and reliability;

- Large side open door and centralized testing points provides excellent maintenance access ability

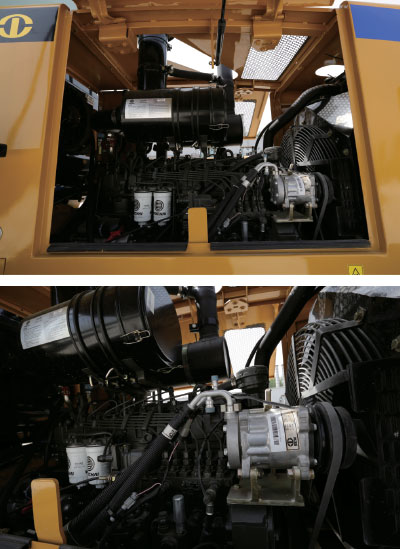

Weichai Engine

The air cleaner provides machine reliability even in the most severe applications

Efficient Hydraulic System

Single pump flow shared system.

More efficiency and larger breakout force

Perfect match between machine speed and hydraulic system to achieve high efficiency

Joystick hydraulic control for easy and precise control

Operator Station

Premium operator station with big space and superior visibility

Patented MAC mount provides less noise and more comfort

Adjustable suspension seat

Sliding side window and AC with fresh air circulation provide operator comfort

Single lever shifting is flexible and convenient

Adjustable air flow outlet delivers better defrost performance

Reliable Drivetrain

Countershaft transmission with upgraded core components provides high reliability

Large rim-pull in 1st gear and higher speed in 2nd gear provide high efficiency for load and carry applications

Clutch cutoff selection switch ensures stable and safe operation

Simply Torque convert and efficiency is high

Shift smooth and comfortable

Advanced Cooling System

High efficiency cooling package

Shock pad mounts ensure reliability under severe applications

Solid Structure

Structures undergo Finite Element Analysis (FEA) and On Machine Stress Analysis (OMSA) to ensure durability

Performance Series (PS) buckets improve loading capability

Serviceability

System pressure test ports are standard

Big angle engine hood side open door provides easy service access

Torque convertor is isolated from transmission making it easy to service

Safety

Safety design complies with all regulatory requirements

Caterpillar Production System (CPS) leveraged in manufacturing process

3-point touching design provides convenient operator entering to cabin

Backup alarm ensures machine safety

|

Item |

Unit | Params |

|

Main Specifications |

||

|

Rated Load

|

kg | 3000 |

|

Operating Weight with Standard Bucket

|

kg | 9900 |

|

Bucket Capacity

|

m³ |

1.5-2.5

|

|

Wheel Base

|

mm |

2740

|

|

Overall Dimension

|

mm |

7305*2354*3182

|

|

Operating Specifications

|

|

|

|

Breakout Force

|

KN |

113

|

|

Dump Clearance

|

mm |

2988

|

|

Articulated Angle

|

37±1

|

|

| Transmission |

|

|

|

Transmission Type Countershaft,power shift |

|

|

|

Transmission Gears

|

F4/R2

|

|

|

Torque Converter Type

|

Single stage 3 elements

|

|

|

Maker & Type

|

SEM TR100

|

|

| Forward I/Reverse I |

7.9/9.7

|

|

| Forward II/Reverse II |

14/31

|

|

| Forward III/Reverse III |

25/NA

|

|

| Forward IV/Reverse IV |

39/NA

|

|

| Axle |

|

|

| Main Drive Type |

Spiral bevel gear, single stage

|

|

|

Final Drive Reduction Type

|

Planetary type, single stage

|

|

|

Rear - Oscillating +/-

|

±12

|

|

|

Engine

|

|

|

|

Model

|

Weichai WP6G125E22

|

|

|

Rated Power

|

kW |

92

|

|

Rated Speed

|

r/min |

2200

|

|

Displacement

|

L |

6.754

|

|

Implement Hydraulic |

|

|

|

Implement System Type

|

Gear pump

|

|

|

Boom Raise Time

|

s |

4.65

|

|

Hydraulic Cycle Time

|

s |

8.34

|

|

System Presure Setting

|

MPa |

18

|

|

Brake System

|

|

|

|

Service Brake Dry & caliper, air to oil control |

|

|

| Parking Brake | "Drum type shoe brake, spring applied & oil released" | |

| Steering System | ||

| Steering System System Type | Shared Flow | |

| Steering Pump Type | Mpa | Gear pump |

| System Presure Setting | 14 | |

| Steering Angle (L/R) | 37±1 | |

| Tires | ||

| Size | 17.5-25 | |

| Type | PR | |

| Layer | 12 | |

| Txtured Type | L-3 |