Track Type Tractor SEM822D

- Efficient: The electronically controlled hydrostatic drive system and multi functional joystick provide high levels of performance and maneuverability.

- Comfortable Operation: The cabin is ergonomically designed for increased operator comfort and visibility. The advanced monitoring system tracks machine operating conditions and keeps the operator informed of all vital machines functions.

- Reliable: The proven hydrostat design along with world class pump and motors provide a highly reliable tractor. The undercarriage components are designed for longer life versus the leading competitor.

- Serviceability: The SEM tractors are designed for easy access to reduce overall maintenance time. The machines electronic control module allows for quick troubleshooting.

| SEM 822D | SEM 822D – LGP | |

| Operating Weight | 24,000 kg | 27,800 kg |

| Rated Power | 175kW/ 235HP | 175kW/ 235HP |

| Blade Capacity | 6,4M3 | 5,5M3 |

Cat ® Product Link™

Cat ® Product Link™ will support your business, and accurately convey information of the equipment to relevant personnel in a timely and effective manner for your better equipment management.

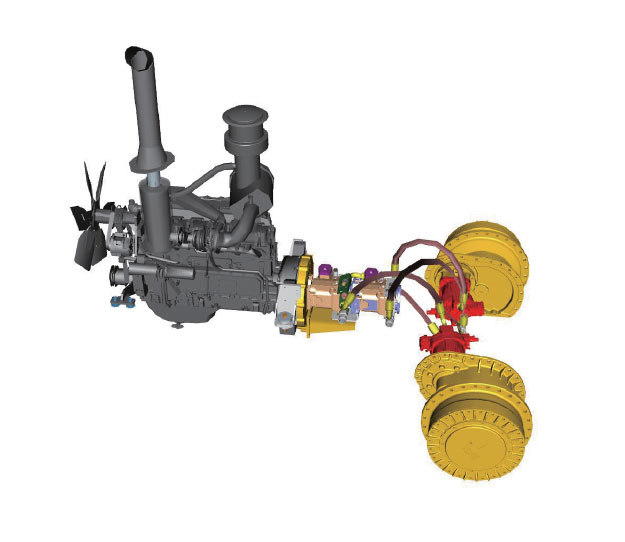

Hydrostatic Drive System

Hydrostatic drive with electronic control technology Maintenance costs are reduced by 60% when compared competitors with torque converter and transmission design. Counter-rotation and power turn feature delivers exc maneuverability on job sites.

Comfortable Operation

Counter rotation—Tracks counter rotate to provide best in class maneuverability. Powered turn-Machine maintains full power through turns to increase productivity. Cruise control—Operators can retain previous speed settings which makes operation easily Multi-function joystick allows for counter-rotation, powered turn and cruise control. Pilot joystick control provides comfortable precise blade operation.

Semi-Universal Blade

SU blade combines the excellent penetration of the S blade and the high production capacity of the U blade. Designed for superior load retention and penetration in tightly packed materials. L-shaped push arms bring the blade closer to the machine, providing excellent maneuverability, balance and blade penetration. Blades feature a strong box section design, made from high tensile strength steel to stand up to the most severe applications.

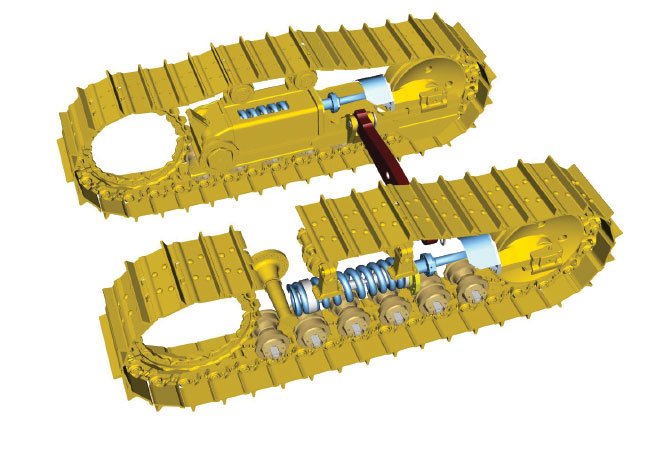

Undercarriage

Undercarriage is provided by a world class supplier ensures high reliability and resistance to wear. Carrier rollers track rollers and idle rollers are all maintenance free. Planetary final drive design delivers increased torque ratio for higher transmission efficiency and lower maintenance cost. Durable final drive bearings and multiple wet disc brakes provide reliability, reduce system heat and extend overall life.

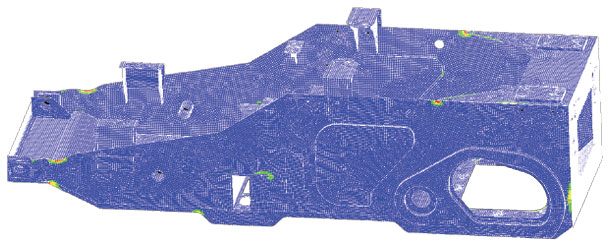

Structures

Machine structures are analyzed using Finite Element Analysis (FEA) and On Machine Stress Analysis (OMSA) to identify and protect high stress areas. Advanced structure welding technique, relieving welding stress.

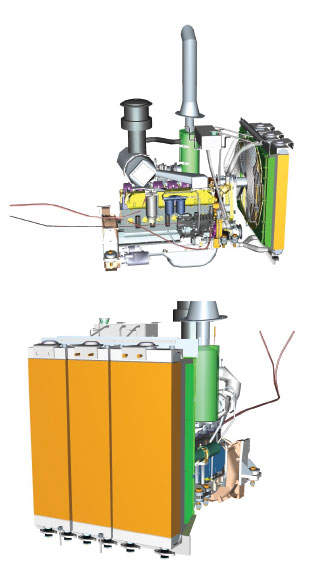

Modular Radiator

New advanced cooling system designed to meet -43°C to +50°C ambient temperatures capability. Modular designed radiator, easy to maintain remove and repair. Radiator grill provides better heat dissipation, easy access for maintenance.

Maintenance

Electronic Control Module (ECM) fault diagnosis system, automatic diagnosis of eight key parameters. Monitoring system provides three levels of alarm, to indicate fault diagnosis. Hydrostatic system has longer service interval (2000 hrs), reduces maintenance time by 50%. Implement valve mounted outside of hydraulic tank provides easy access to check and service.| Item | Unit | Params |

| Model | ||

|

Operating Weight

|

kg | 23,680 |

|

Ground Pressure

|

kPa | 70 |

|

Ground Clearance

|

mm | 394 |

|

Max.Slope

|

°

|

30 |

|

Engine

|

||

| Model |

Weichai WD10G178E26

|

|

|

Flywheel Power

|

162 kW / 220 hp

|

|

|

Working Tool

|

|

|

|

Blade Type

|

SU

|

|

|

Blade Capacity

|

m³

|

6.4 m³ (U 7.5 m³ )

|

|

Blade Width

|

mm

|

3,720 mm U 4,015 mm

|

|

Blade height

|

mm

|

1,511 mm U 1,420 mm

|

|

Max. Blade Digging Depth

|

mm

|

563

|

|

Max. Blade Lift Ground Clearance

|

mm

|

1,140

|

|

Max.Output Rimpull

|

kN

|

350

|

|

Maximum Digging Depth Of Ripper

|

mm

|

650

|

|

Maximum Clearance Under Tip

|

mm

|

640

|

| Powertrain |

|

|

| Type |

|

Electronic control, Dual-path, Hydrostatic Drive

|

| Travel Speed- F/R |

km/hr

|

0 - 11.5 km/hr (Infi nitely Variable Speed Control)

|

| Steering & Brake |

|

Hydrostatic Steering, Wet, Multiple-Disc Brakes

|

| Minimum Streeing Radius |

mm

|

4,225 mm (Counter-rotated avaliable)

|

| Undercarrige |

|

|

|

Track Shoe Width

|

mm

|

560

|

|

Track Shoe Quantity

|

piece

|

40

|

|

Length Of Track On Ground

|

mm

|

2,948

|

|

Track Gauge

|

mm

|

2,000

|

|

Track Roller Quantity

|

|

7/Side

|

|

Carrier Roller Quantity

|

|

2/Side

|

|

Hydraulic System

|

|

|

|

Type

|

|

Pilot Control

|

|

Implement Hydraulic System Pressure

|

Mpa

|

19

|

| Service Refill Capacities | ||

|

Cooling system

|

L

|

45

|

|

Hydrostatic Oil

|

L

|

62

|

|

Implement Oil

|

L

|

110

|

|

Fuel

|

L

|

460

|

|

Pivot Shaft Case (each side)

|

L

|

0.8

|