Wheel Loader SEM660D

- High Productivity

- Best-in-class Reliability and Durability

- Excellent Fuel Economy

- Outstanding Operator Comfort

| Rated Load | 7,000kg |

| Operating Weight | 16,800kg |

| Bucket Capacity | 4.0 m³ GP – 5.5 m³ CB |

Optimized Engine

Low speed engine with E-fan provides increased operating efficiency Enhanced fuel pre-filter eliminates water and contaminant from fuel for best fuel system protection The 93 desert type air cleaner provides machine reliability in most severe applications. Oil-bath type oil filter is optional

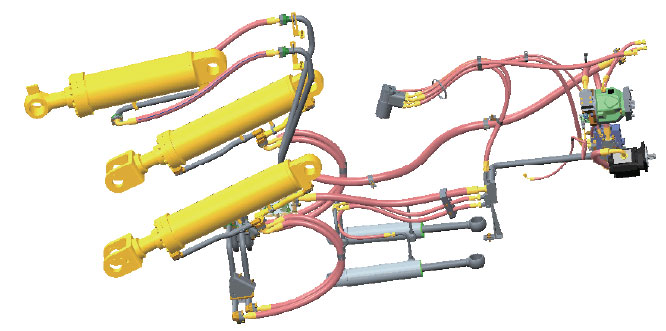

Efficient Hydraulic System

The advanced load sensing hydraulic system with flow sharing circuits improves efficiency World Class hydraulic components ensure high reliability The optimized hydraulic system paired with the drive train reduces machine cycle time and increases productivity Relocated hydraulic oil tank ensures hydraulic pump’s life

Operator Station

Premium operator station improves cab sealing and visibility Sliding side window and AC with fresh air circulation provide operator comfort Integrated relays and fuse panel. Single cabin harness connection plug provides easy service access Joystick hydraulic control for easy and precise operation命 Multi-function instrument dashboard with 3-level alarm Adjustable suspension seat

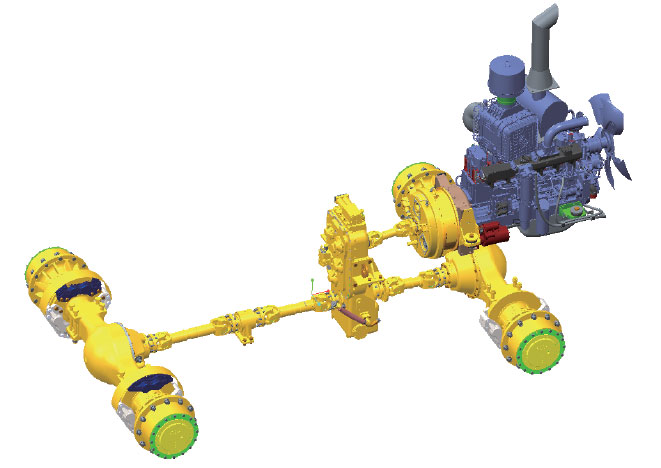

Reliable Drivetrain

Countershaft transmission with upgraded core components provides high reliability Large rim-pull in 1st gear and higher speed in 2nd gear provide high efficiency for load and carry applications Clutch cutoff selection switch ensures stable and safe operation The SEM designed and built axle equips with 10 calipers (6 for front and 4 for rear), it delivers better brake performance and longer service life

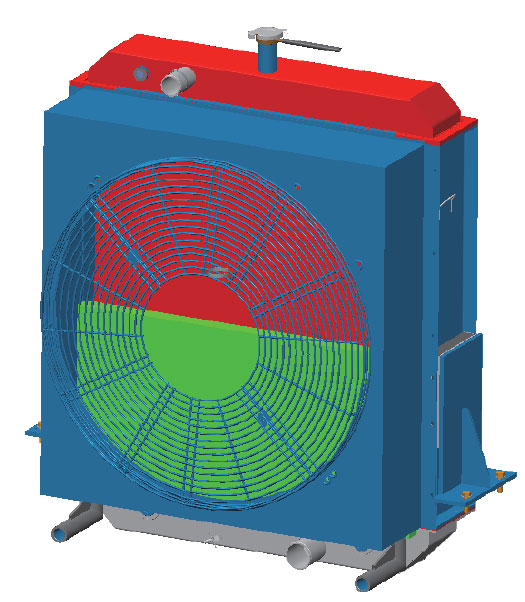

Advanced Cooling System

The standard cooling package provides high reliability in 43°C ambient conditions. An optional package is available for 50°C ambient conditions Shock pad mounts ensure reliability under severe applications

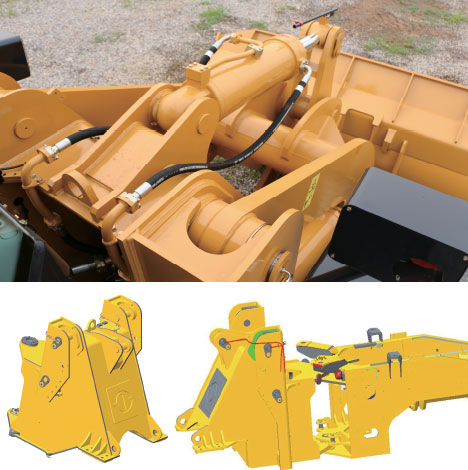

Solid Structure

Structures undergo Finite Element Analysis (FEA) and On Machine Stress Analysis (OMSA) to ensure durability Performance Series (PS) buckets improve loading capability Steering robber stopper design provides protection for frame

Serviceability

Torque convertor is isolated from transmission making it easy to service Simple structure countershaft transmission delivers low maintenance cost Centralized lubrication points reduce maintenance time System pressure test ports are standard Easy access to external air charge connecting port Engine hood grill opens for easy service access It is easy to change brake discs with new split type caliper

Safety

Safety design complies with all regulatory requirements Caterpillar Production System (CPS) leveraged in manufacturing process 3-point touching design provides convenient operator entering to cabin Backup alarm and beacon ensure machine safety Environment-friendly painting process

Multiple Applications

SEM660D can be widely used in port cargo handling mineral yards, steel mill,and other high productivity demand applications In aggregate site, coal loading and construction etc loosen material handling utilization applications,SEM660D can load more, move faster and burn less Multiple work tools for selection| Item | Unit | Params |

| Main Specifications | ||

| Rated Load | kg | 6 000 |

| Operating Weight with Standard Bucket | kg | 20 000 |

| Bucket Capacity | m³ | 3.3-5.5 |

| Wheel Base | mm | 3 350 |

|

Overall Dimension (outside of tire)

|

mm

|

8 414X3 370X3 458 |

| Operating Specifications | ||

|

Breakout Force (GRD)

|

kN | 183 |

| Dump Clearance | mm | 3 048 |

| Articulated Angle |

°

|

38±1 |

| Transmission | ||

|

Transmission Type

|

Countershat, power shift | |

|

Transmission Gears

|

F4/R4 | |

|

Torque Converter Type

|

Single stage 3 elements

|

|

|

Maker & Type

|

TR200

|

|

|

Forward I/ Reverse I

|

km/h

|

7.4/7.4

|

|

Forward II/ Reverse II

|

km/h

|

14/14

|

| Forward III/ Reverse III |

km/h

|

22/22

|

| Forward IV/ Reverse IV |

km/h

|

38/38

|

| Axle |

|

|

|

Main Drive Type

|

|

Spiral bevel gear, single stage

|

|

Final Drive Reduction Type

|

|

Planetary type, single stage

|

|

Rear - Oscillating +/-

|

°

|

±11

|

|

Engine

|

|

|

|

Engine Model

|

|

WD10G240

|

|

Rated Power

|

kW

|

178

|

|

Rated Speed

|

r/min

|

2 000

|

|

Displacement

|

L

|

9.726

|

| Implement Hydraulic |

|

|

|

Implement System Type

|

|

Single load sensing flow sharing system

|

|

Boom Raise Time

|

s

|

5.3

|

|

Hydraulic Cycle Time (rated payload)

|

s

|

9.7

|

|

System Presure Setting

|

Mpa

|

18

|

|

Brake System

|

|

|

|

Service Brake

|

|

Dry & caliper, air to oil control

|

|

Parking Brake

|

|

Drum type shoe brake,spring applied & oil released

|

|

Steering System

|

|

|

|

System Type

|

|

Flow Amplifying

|

|

Steering Pump Type

|

|

Piston pump

|

|

System Presure Setting

|

Mpa

|

18

|

|

Steering Angle (L/R)

|

°

|

38±1

|

|

Tires

|

|

|

|

Size

|

|

23.5-25

|

|

Type

|

|

Bias

|

|

Layer

|

|

20

|

|

Textured Type

|

|

L3/E3

|